Part 15:

"These

are the times that try men's souls"

OK, so I know this wasn't first penned by a boat owner but it could have

been. Up until now I have been writing

this sporadic blog somewhat chronologically, or at least the way I remembered

it. This time I am grouping all the

items under the single subject irrespective of chronology ( I put all those big

words in for my editor) and memory.

I Got The Low-Down, Breakdown,

Boatyard Blues; and

on the flip-side Money! To quote my musical muse, Jimmy Buffett:

"Now don't get me wrong, this is not a sad song. Just events that I have

happened to witness." S/V Caribbean

Dream is a 10 year old boat and things do break even on new boats. Saltwater is a harsh environment and the

stresses placed on mechanical and manual systems are tremendous, but

really….UNCLE! When it comes to

maintenance and repairs there are several types. First, scheduled, i.e. the oil on the two

auxiliary engines gets changed every 150 hours and the generator every 200

hours. That you see coming and can plan

for it. Then there is annual or semi-annual

maintenance. Bottom paint, changing

impellers, belts, fuel filters, and washing and waxing, although washing is

more of, or should be a weekly occurrence, for example. Then

there are unexpected repairs/expenses some of which can represent an emergency,

some merely an inconvenience. These are

the ones that you don't always see coming and as such hit your pocket book

hard; very hard. Finally there are

upgrades or refits that don't necessarily need to be done but it would make

life easier.

We will

leave scheduled maintenance for now and start with annual maintenance, and that

takes us to the boatyard. We hired a

captain to help us move CD to the Nanny Cay lift since my last experience with

backing into a slip was so disastrous.

While there, the plan was to deal with some annual, some unexpected, and

some desired upgrades. First and foremost was bottom paint or antifouling paint

applied below the waterline to retard marine growth such as algae and

barnacles. There is great debate on the subject of what is the best paint and

its eco friendliness or lack thereof.

One thing is for certain, it is expensive paint and you want to or have

it done right. We decided to take the

advice of the boatyard manager and use a product banned in the upper 48 and add

some tin booster to it for good measure.

Since we did not know what we were doing we decided to have it

"professionally" applied. The

process is messy, and involved sanding off or roughing up the old paint (I am

still finding black paint dust almost 4 months later.) Of course there was this add-on and that

add-on and why not add washing the salt residue off the underside and scraping

the props while I am at it. I will say

it did look nice when finished, but here 4 months later not only is it (the paint)

chipping off there are sections where it has worn away completely; so much for

18 months of service as promised, but it was "professionally"

applied. Several days before the haul

out… I should stop here and talk about

the haul out. This is a process where

they but two large straps under your boat and then a big lift does just that,

lifts your boat out of the water. This

lift is on four very large wheels and the driver then takes your home/boat out

of the water and it is pressure washed to get the growth (slime, barnacles,

etc) off the bottom before it is moved over to the yard where it is placed up

on blocks. Kind of like the car you were

perpetually working on as a teenager or the Junker across the street that will

never run again. Whichever analogy works,

it looks like the Big Bad Wind might just huff and puff it down. It is also a good 15 feet off the ground so

climbing up into it is a pucker inducing exercise; well at least for this old

fat guy.

At the point

it is in the yard the afore mentioned "professionals" began to do

their thing on the bottom. Oh yes,

several days before the haul out I noticed water in the port bilge, and it was

salty tasting. Remember your mom telling

you not to put that in your mouth, well the fastest way to tell what kind of

liquid it is and where it might be coming from is to taste it. This is especially special when there is fuel

in the water; more to come on that one.

As I said, this tastes salty and with a boat in the ocean the salty

tasting stuff is supposed to be on the outside of the boat or on the rim of

your margarita. So I contracted one of

the maintenance companies to check all of the thru hull fittings. These are holes in you watertight boat

below the waterline; you know, where the wet stuff is. Well, they went through each one and

determined I needed to replace two of the shutoff valves called seacock's that

allow you to shut off the flow of water if the hose connected to it fails, thus

eliminating the eventual filling of your home/boat with its surrounding

environment. OK worthy investment, and

guess what, to replace the seacocks you also need to replace the actual thru

hull fitting that goes through the hull of the boat. I watched and learned and two grand later I

had 2 new seacock's and thru hulls ( there are 14 on our boat total) but they

were "professionally" done so of course they leaked because the

"professionals" did not tighten the interior hose clamps and once in

the water they leaked and had to be tightened.

I did get to observe the process and see the hull construction of CD

when they ripped the old thru hulls out.

I have never been a fan of balsa core boats (guess I crashed too many of

those cheep balsa airplanes as a kid), one of which CD is, but I must say the

thickness of the hull and the outer layer of fiberglass was impressive. For those not sure what I am talking about,

in the old days when boats were made of wood there were the wooden ribs of the

hull and then planks fitted tightly together and when the boat went into the

water the planks swelled and the hull below the waterline was

watertight(ish). Above the waterline

they were often painted with pitch to seal the planks. In modern fiberglass boats there are many

ways to construct the hull, one popular way being an inside layer of fiberglass

then a core material like end-grain balsa or foam and then an outer layer of

fiberglass all squeezed together (vacuum bagging) or sometimes hand laid

up. For those of you who are boat

people, please don’t have a tizzy over this over simple explanation, rife with

over simplifications, it's not a technical blog after all. Well all-in-all, CD's hull looked to the uninformed

new boat owner very solid and has given me no reason to question it since. Even after I bumped the starboard keel over a

reef that was mislabeled on the chart.

Think skinned knee.

So to recap;

bottom job underway, new seacock's and thru hulls in process. For those keeping score that's boatyard up

$8K, me down that same amount. The one

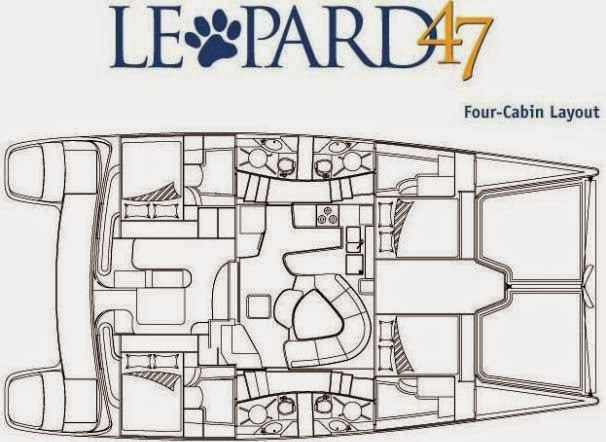

big thing I wanted to have happen while there, were needed engine access ports created. If you go back an entry or two I talk about

the engine access on the Leopard 45/47 which is fine if you are very short,

very limber, and very skinny. Which of

those apply to me?…..yup-0. So before we

even thought of considering a Leopard I researched the possibility of cutting

away part of the area under the aft

berths to gain access from above instead of just through the furthest aft

outside hatches that are located on the steps up from the water to the main

deck; these are called the sugar scoops. The designed access is for you to go

into the sugar scoop and crawl through another removable hatch into an enclosed

and hot engine room. Now I will say that

access to engine rooms and space allotted them are usually not high on a

designer of a charter boats' mind. The

point is comfort for the charterers who will not be working on the boats,

that’s for the mechanics in the yard to do and they are paid to be

miserable. So I needed to make sure that

opening the area over the engine and under the aft mattress would be structurally

safe. I talked to several people on

several web sites and most importantly on the Leopard Owners Group. I found in

the archives a brief email from the original designer of the boat: the word was

that it was ok to do and would not damage the structure of the vessel if you did

the following, and went on to list some parameters that I made note of. I

emailed the person who surveyed the boat and he gave me the name of a person in

the boatyard who would do an excellent job, so I contacted him. He came and looked at the project and made

some suggestions in how it could be done and even though the boat was up on

blocks right outside of his shop that was pretty much the last time I saw him

until November when we had to go into a marina to deal with a fuel tank

problem. Several days later I got an

email from his wife wanting to know if we still needed the work done. Let's see, August to November, you might be

good enough to wait for a few weeks for but almost 4 months for, no. I think I'll answer her email in March. Luckily the person the previous owners had

watching the boat knows a lot of the trades people in the BVI and was able to

hook us up with a carpenter to do our hatches a few weeks after the boat was

back in the water. It was supposed to

happen during the three weeks we were back in the States so of course it took

five, you know, Island Time Mon. They do

however provide easy access to the engine rooms and are sturdily made so you

can only open half of them if you are only checking oil, coolant, etc. But, back to the boatyard saga, the last big

thing on the haul out list was to fix the water maker. For a number of reasons I won't go into here, the watermaker, a magical

device that using diesel, multiple filters, and high-pressure turns sea/saltwater into drinkable

fresh water. You need the diesel to run

the generator to power the watermaker and it makes water at a rate of about 50

gallons an hour. The generator burns

about 1/2 gallon an hour at about $5.00 a gallon so by island rates it is

pretty cheap water, and very tasty too.

The watermaker was finally looked at just as we were put back in the

water and about to head back to our marina slip and the problem was determined

and parts were ordered and a week or so later we could make water… just not in the marina where we were tied up since

that local bay water was/is near toxic.

Thus ends

our first haul out experience. Oh yes, I

should mention how the pricing works down here.

There is the boatyard itself.

Their rates are pretty straight forward; it's x-amount for a haul out,

this amount for a bottom wash, and so on.

If you have the yard buy the supplies it is more than if you buy them yourself

so you set up an account at the chandlery (boat stuff store) and get a slight

discount and it's off to the races. Then

there are the trades persons in the yard.

For example, my docking boo-boo needed to be fixed and I found a similar

one on the other side, that I didn't do, so I go to the painter whose prices

are not so fixed and he provides me a quote "range"; well you know

how that works out so just plan for the top of the range. Next there is contracting the yard workers to

do the work the yard would pay them for but charge you more for, adding their

percentage. This usually is facilitated

by a third party, in this case the guy watching our boat who became our

"go-to" guy for skilled labor.

He would introduce you to yard person "A" and they would have

a quick conversation in the local dialect I have not nor will ever master. Then your "go-to" guy leaves and

tells you that you and person "A" will have to talk about a price; ok

there's really no talking, you're given the price and agree or not to have the

work done. Then once you agree person "A" has person "B" or

"C" or more do the work. On

the positive side, you directly help the local economy and get work done maybe a

little cheaper. On the downside, you

best be on them like a hawk because if they don't do the work to your liking

you have little to no recourse; what are you going to do go complain to the

yard? Boatyards also have unwritten

rules, like you use the boatyard approved labor not outside contractors. Like any unwritten rule there are ways around

that, that's what your "go-to" guy (ours was an outside contractor)

is there for.

You might

ask, "Lizards, do you stay on the boat during all this work?" Hell NO says the wife! It is hot, windless, and dirty so you get a

hotel, usually located at or near the yard and run the air-conditioning at full

and take long hot showers. Now at some yards you can stay on the boat, and if

you have shore power so at least you have your refrigeration and fans, and

especially if you are doing the work yourself you can and often do stay on the

boat, but the boatyard at Nanny Cay was also a place boats go to ride out the

hurricane season so abundant cooling breeze in there is not desirable. Neither were restrooms, shower facilities,

power, or water so hotel it was. All

good things must come to an end, so the saying goes. There are many reasons for

this, one is your holiday is up and it's time to go back to work or maybe it's

because the money is gone. Well in our

case the work was mostly done and more money would be gone if we didn't get the

boat back in the water so the painful process of watching them strap up our boat

and take her off the chocks and move her begun.

There is a lot of angst in this and you ask yourself certain questions

like, did all the thru hulls and associated hoses really get reattached? Yup that's a big one. Well she went in and our "go-to

guy" helped us start the systems up.

First the generator so the watermaker guy could determine what was

wrong. Now the generator is just another

diesel engine and is cooled by sea water being pumped in past its version of a

radiator and then expelled, so no water coming out of the boat means no water

coming in which means you generator will overheat and if left long enough your

wallet will be considerably lighter. So

you guessed it, started the genny and no water came out, the temp gage did

shoot up so we quickly turned it off. After

some quick assessment we primed all the engine pumps and water came in and went

out properly and it was off to the fuel dock, only problem is we lost our watermaker

guy. He eventually came over to the

fuel dock and did a preliminary assessment and went away to meet us later at

our slip in our, for now, home marina.

So off we went back to Village Cay, new bottom paint, two new thru hull

fittings and seacocks but still no engine access and no watermaker. When we got back to Village Cay a fellow

Leopard owner came down and commiserated regarding the cost but explained it

thusly: 'buying a boat is just the

entrance ticket to the carnival after that you have to pay for each ride'.

As I said,

not all of the work we needed done had been done but over the course of the

next two months the engine accesses were finally completed and new and more expensive rides at carnival

were to be experienced. One involved our

starboard fuel tank developing a leak when it was full of 78 gallons of diesel

and to make things worse (really they can always get worse) we were in St.

John, a National Park, in the U.S.V.I so had we had dumped any of our fuel the

fine would have been exorbitant. We made

it back to the B.V.I., not 15nm from where we were but where there is no EPA

and found a marina near where the guy who has become our "go-to"

engine/mechanical/electrical guy, is located.

Several days later we had a new bottom welded on the fuel tank and the

ride on the tilt-o-wheel was over… until next time.

Well we are now

sitting in a perfectly lovely anchorage off Water Island U.S.V.I. in a bay the locals call Honeymoon Bay. If you like 'Lizards on Ice' on Facebook or follow me on Facebook you have

seen some of the spectacular sunsets witnessed from this bay. We had planned to be in St. Croix by now or

even St. Maarten but when anchored in 45' of water off Norman Island in the

B.V.I., where I needed to put out at least 200' of the 300' of chain I have

attached to the anchor, somewhere past foot 120 was a lot of rust, I mean 'turn

the water rust red and rusty flakes of metal were flying off' rust, so we

needed a new chain. Now you can't or shouldn't run out to Home Depot for this kind

of chain and it is expensive, no tilt-o-whirl kind of expensive or like a

rollercoaster but we had a guy recommended by the former owner and another

sailing friend we have met here and I gave him a call. Now this guy and his warehouse could fill a whole

season of 'Hoarders' and he has turned out to be a most fascinating person, but

the size of chain I needed 300' of he had just cut his last 300' piece the day

before I called him; no problem, more should be here in 10 days. Well you guessed it that was 20 days ago but

no worry, maybe tomorrow. In the mean

time we picked up a new family car a.k.a. a dingy smaller than the old one that

Jo can easily drive and have enjoyed some lovely sunsets and met some more fascinating

people. At the time I am writing this it

is 11 days before Christmas and we have some decorations up and are getting

into the spirit and getting into the spirits, come on it is the Caribbean and

are excited by what 2015 will hold in store.

More tickets for rides at the carnival, but I might also beat the barker

at the sideshow games and win a big stuffed parrot!

Merry

Christmas and a Happy New Year to my land based and seagoing friends, and to

leave with a thought from Jimmy Buffett: Ho-Ho-Ho and a bottle of rum, Santa's runoff

to the Caribbean!

|

| How to get 17.7 tons out of the water. A real "pucker" moment |

|

| Blocked up and ready for action |

|

| Prep for paint, prop still to be cleaned |

|

| I just kept telling myself, professionals did it |

|

| The often mentioned thru hulls |